Every restaurant needs a working chef counter or island. Each one looks different, but the job is the same: keep the line organized, keep plates moving, and flex with menu changes without tearing the kitchen apart. My approach is simple: modular where it matters, bolt-together for serviceability, and future-proofed utilities so you can adapt without calling a demo crew.

Modular & swap-ready refrigeration

Gone are the days of built-in refrigerated islands. I leave open bays so standard prep tables can slide in. When a menu changes or a unit fails, just swap and go—no installer needed.

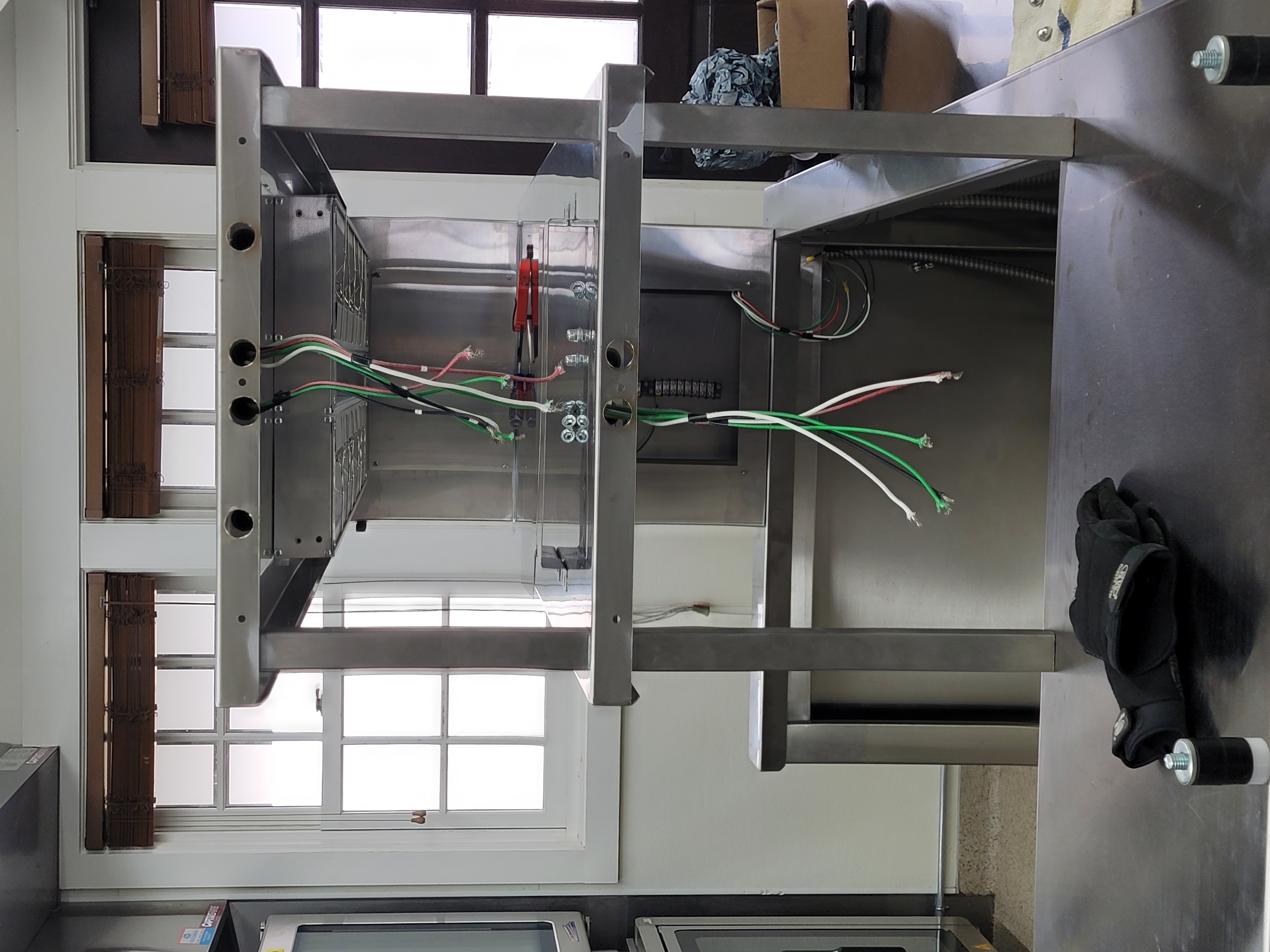

Dedicated electrical load center

A built-in load center feeds both high and low voltage runs. It lowers install cost today and gives you clean capacity to add a printer, POS, or warming drawer later.

Bolt-together frames

Every section bolts together. If you ever need to move, replace, or reconfigure, you can disassemble without a grinder—and without leaving gaps that are hard to clean.

Design must-haves

- Two pass-through shelves: one for smallwares storage; one with heat lamps for finished plates to the expo side.

- Open bays for refrigeration: dedicated receptacles in the load center make equipment changes painless.

- Built-in electrical chases: keep high/low voltage tidy and protected.

- Customizable modules: dial in to your space, ceiling height, and menu.

Rules of thumb I use on every build

- Start with the plate size. Your largest plate drives the pass-shelf depth and dish storage. Tight on space and only using 10″ plates? We can trim the shelf and reclaim aisle width.

- Use your ceiling. If heights allow, I’ll add a pot-rack shelf above the pass—vertical storage = faster reach and fewer steps.

Common mistakes to avoid

- No dish cabinet on the expo side. Plates wander and backups grow. I integrate a bolted dish cabinet so there are no gaps and cleanup is easy.

- Ignoring real plate sizes. Spec the shelf and storage off actual dinnerware, not guesses.

Case study: Erin Hills Golf Course (WI)

The challenge: a small kitchen that kept getting busier. Over time, shelving and ad-hoc stations crept onto the line—more storage, less efficiency.

My solution: a custom, modular chef counter with open refrigeration bays, dual pass shelves, and a dedicated load center. Storage went vertical; the line got its space back.

The outcome: the kitchen now supports breakfast, lunch, and dinner without full tear-downs between services. Ordering got simpler, and the right equipment lives exactly where it works best.

Want ideas for your space?

Ask me for more design inspiration. I’ve built a lot of chef counter models and can tailor one to your menu, crew, and footprint.

Get in touch See projects